Get There Faster.

News by ModuleWorks: ModuleWorks and Cetim Partner on Costing Software

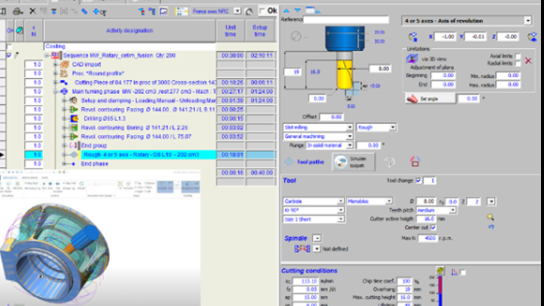

Machine shops and sub-contractors use TechniQuote cost estimation software to generate detailed cost breakdowns and make informed decisions about pricing, process optimization and resource allocation for mechanical manufacturing. To generate an estimate, users load a CAD model and set up the machining scenarios. For milling jobs, the integrated Self-Driving CAM enhances TechniQuote with pre-defined machining templates to simplify and accelerate the cost estimation process.

“Estimations based on toolpath data are more accurate than those based on other costing methods, but both skill in machining and time are required to enter relevant CAM parameters. With machining rules and data provided by TechniQuote and with Self-Driving CAM, users now just select very few parameters that control pre-defined CAM templates. This greatly speeds up the estimation process and users can respond rapidly with accurate pricing,” says Hervé Lallemand, Costing Product Manager at Cetim.

“Toolpath-based cost estimation is a novel application of our Self-Driving CAM, and it’s great to see how TechniQuote is using it to further automate and simplify its costing workflows,” says Soroosh Eghbali, Head of Technology CAM Automation at ModuleWorks.

TechniQuote uses automatic feature recognition in addition to the machining templates to help engineers quickly set up and run comparative cost analyses. The integrated Self-Driving CAM is built upon the ModuleWorks toolpath algorithms which deliver precise information on the length and complexity of the toolpath, enabling TechniQuote to accurately estimate the total machining time as well as other cost factors such as tool wear, waste material and overall energy consumption.

Download Press Release & Images

About ModuleWorks

ModuleWorks is the leading software component provider for the digital manufacturing industry. With over 200 employees and 1500 person-years of software development, ModuleWorks’ expertise in toolpath creation and simulation is recognized throughout the industry and its software components are already optimizing the performance and quality of over 500,000 installed seats of CAD/CAM and CNC software around the world. From standard products to exclusive development projects, ModuleWorks helps companies to bring their vision of Industry 4.0 to life. With its comprehensive portfolio of cutting-edge software components, ModuleWorks enables its customers to optimize their CAD/CAM solutions and connect to CNC/MTB systems to increase their competitiveness and help them Get There Faster.

About Cetim

Cetim, Technical Center of Mechanical Industries, has been supporting innovation & competitiveness of companies thanks to its multidisciplinary skills, digital expertise and unique R&D capacity. With its International subsidiaries and 8000 customers in more than 30 countries, Cetim has become a world leading player to overcome environmental and Industry 4.0 main challenges with innovative solutions and services in the field of testing/control & measurement, product/process engineering, consulting & training and outsourced R&D.

For more information about the Cetim Global Solution and Services, please visit https://www.cetim-engineering.com/

Machine shops and sub-contractors use TechniQuote cost estimation software to generate detailed cost breakdowns and make informed decisions about pricing, process optimization and resource allocation for mechanical manufacturing. To generate an estimate, users load a CAD model and set up the machining scenarios. For milling jobs, the integrated Self-Driving CAM enhances TechniQuote with pre-defined machining templates to simplify and accelerate the cost estimation process.

“Estimations based on toolpath data are more accurate than those based on other costing methods, but both skill in machining and time are required to enter relevant CAM parameters. With machining rules and data provided by TechniQuote and with Self-Driving CAM, users now just select very few parameters that control pre-defined CAM templates. This greatly speeds up the estimation process and users can respond rapidly with accurate pricing,” says Hervé Lallemand, Costing Product Manager at Cetim.

“Toolpath-based cost estimation is a novel application of our Self-Driving CAM, and it’s great to see how TechniQuote is using it to further automate and simplify its costing workflows,” says Soroosh Eghbali, Head of Technology CAM Automation at ModuleWorks.

TechniQuote uses automatic feature recognition in addition to the machining templates to help engineers quickly set up and run comparative cost analyses. The integrated Self-Driving CAM is built upon the ModuleWorks toolpath algorithms which deliver precise information on the length and complexity of the toolpath, enabling TechniQuote to accurately estimate the total machining time as well as other cost factors such as tool wear, waste material and overall energy consumption.

Download Press Release & Images

About ModuleWorks

ModuleWorks is the leading software component provider for the digital manufacturing industry. With over 200 employees and 1500 person-years of software development, ModuleWorks’ expertise in toolpath creation and simulation is recognized throughout the industry and its software components are already optimizing the performance and quality of over 500,000 installed seats of CAD/CAM and CNC software around the world. From standard products to exclusive development projects, ModuleWorks helps companies to bring their vision of Industry 4.0 to life. With its comprehensive portfolio of cutting-edge software components, ModuleWorks enables its customers to optimize their CAD/CAM solutions and connect to CNC/MTB systems to increase their competitiveness and help them Get There Faster.

About Cetim

Cetim, Technical Center of Mechanical Industries, has been supporting innovation & competitiveness of companies thanks to its multidisciplinary skills, digital expertise and unique R&D capacity. With its International subsidiaries and 8000 customers in more than 30 countries, Cetim has become a world leading player to overcome environmental and Industry 4.0 main challenges with innovative solutions and services in the field of testing/control & measurement, product/process engineering, consulting & training and outsourced R&D.

For more information about the Cetim Global Solution and Services, please visit https://www.cetim-engineering.com/