492

Follower

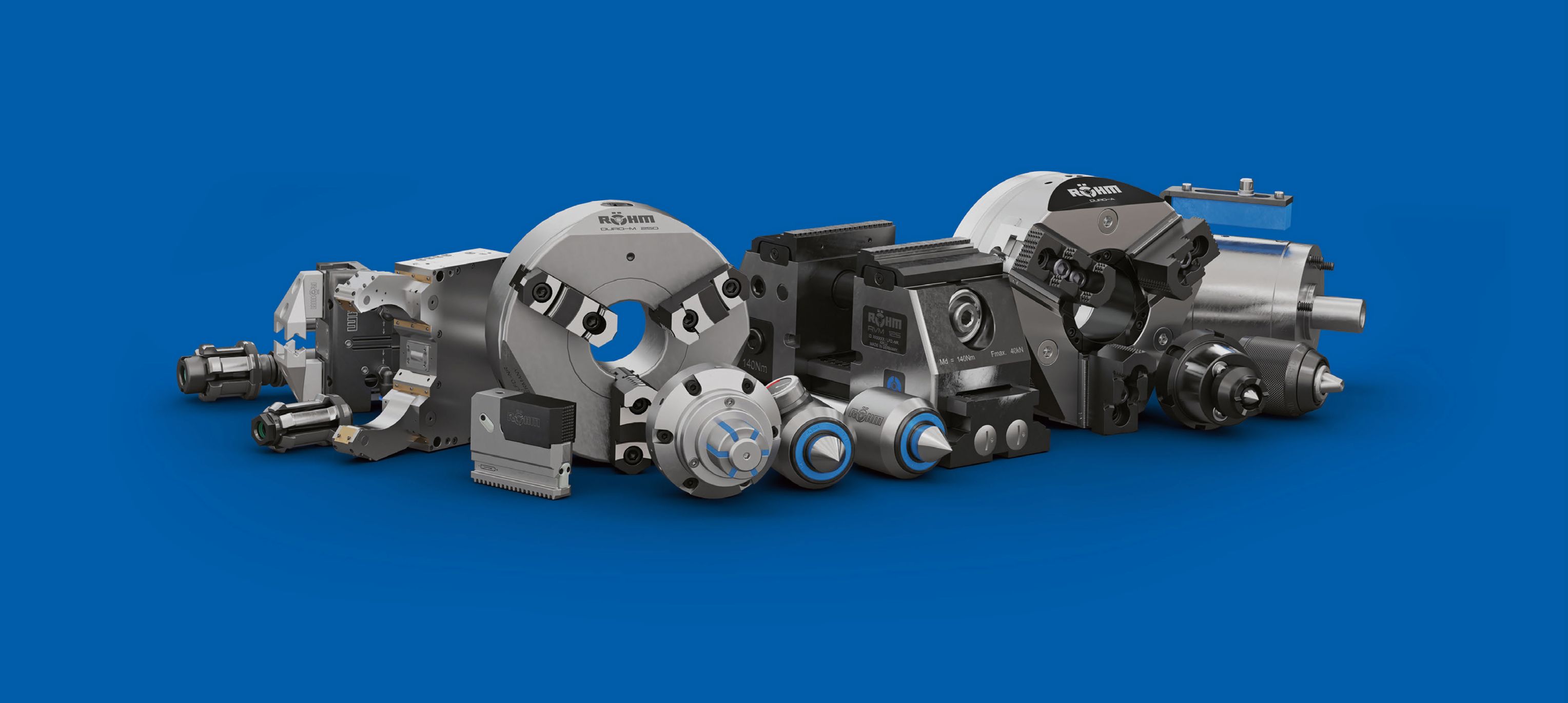

Mandrels - Collet chucks

RÖHM

PDF |5,49 MB | 96 Seiten | 04.04.2019

PDF |5,49 MB | 96 Seiten | 04.04.2019 Mandrels

Modern manufacturing technology can hardly do without the use of segment clamping mandrels. In the fields of precision machining, turning, grinding, gear cutting and checking, segment clamping mandrels assume important tasks that are associated with challenging conditions. The innovative rubber segments enable a great elongation of the clamping sleeve to 1.2 mm.

Collet chucks

The new and modular CAPTIS clamping system is impressive in both rotary applications in lathes and in stationary use in drilling, milling and machining centres and measuring machines. The conversion from outer to inner clamping can be done in less than 1 minute with the innovative and patent-pending quick changing function. The encompassing clamping enables precise concentricity and repeatability of 0.005 mm without deforming the workpiece.

ADVANTAGES AT A GLANCE

- Highest flexibility due to modular construction

- Precise concentricity and repeatability of 0.005 mm

- Compact and weight-reduced construction for a larger work area

- Short tooling and non-productive times thanks to the great elongation of the clamping sleeve up to 1.2 mm

- Vibration dampening and long service life thanks to innovative vulcanisate of the clamping sleeves

- Fast replacement of the clamping mandrel thanks to the patented bayonet quick change system