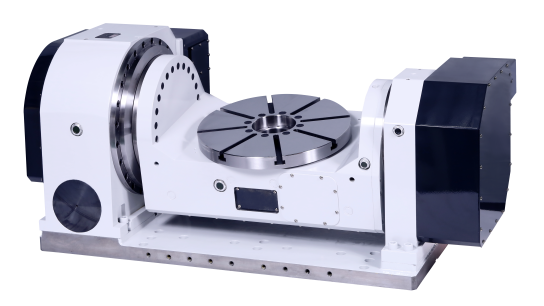

ZERO-BACKLASH Roller Cam Table

Roller cam drive

Features advantages:

1. Zero backlash:

Rolling contact between the roller and the cam, no

positive reversal backlash problem, greatly improving the

ultra-precision characteristics of the roller cam, reducing

the defect rate and improving the quality, which is a

breakthrough for precision machining technology.

2. Ultra-high efficiency conduction:

Roller cam type turret conducts in rolling mode,

reduces wear, high transmission efficiency, high

speed operation, and conduction efficiency of over

90%.

3. No thermal displacement:

Even at high speeds, reduce friction, reduce thermal

displacement, improve quality stability, and reduce

non-performing rates.

4. Maintenance-free:

Due to low wear and low aging, it can maintain initial

accuracy for a long time.

5. Long life:

Roller conduction method, can reduce wear and have

long service life.

6. Braking performance:

When the brake is positioned, the disc surface will not

sway back and forth, and the positioning brake will

remain within 2um, which can highly demonstrate the

precision machining quality.

Roller cam drive

Features advantages:

1. Zero backlash:

Rolling contact between the roller and the cam, no

positive reversal backlash problem, greatly improving the

ultra-precision characteristics of the roller cam, reducing

the defect rate and improving the quality, which is a

breakthrough for precision machining technology.

2. Ultra-high efficiency conduction:

Roller cam type turret conducts in rolling mode,

reduces wear, high transmission efficiency, high

speed operation, and conduction efficiency of over

90%.

3. No thermal displacement:

Even at high speeds, reduce friction, reduce thermal

displacement, improve quality stability, and reduce

non-performing rates.

4. Maintenance-free:

Due to low wear and low aging, it can maintain initial

accuracy for a long time.

5. Long life:

Roller conduction method, can reduce wear and have

long service life.

6. Braking performance:

When the brake is positioned, the disc surface will not

sway back and forth, and the positioning brake will

remain within 2um, which can highly demonstrate the

precision machining quality.